The intake manifold gaskets have been replaced and I was really hoping things would be easier from here. Unfortunately things are just getting started. The car is still running rough, but not as rough as it was before I took it in.

The real reason I took the car in to my mechanic, was to resolve the misfiring issue. It was very clearly running on only 7 cylinders when I took it in. It was me who asked them to change the intake gasket because I was aware of the vacuum leak and I wanted to be sure that was resolved to try and getting it running smooth.

My mechanic did his best to get it sorted and replaced the fuel injectors and spark plugs which did make a small difference, but it’s still not running anywhere near as smooth as it was 12 months ago. So there’s clearly something else going on. My mechanic believes the issue could be with the fuel distributor. But I’m not totally convinced that this is the problem and it’s a rather expensive part. So this is where I have taken things into my own hands.

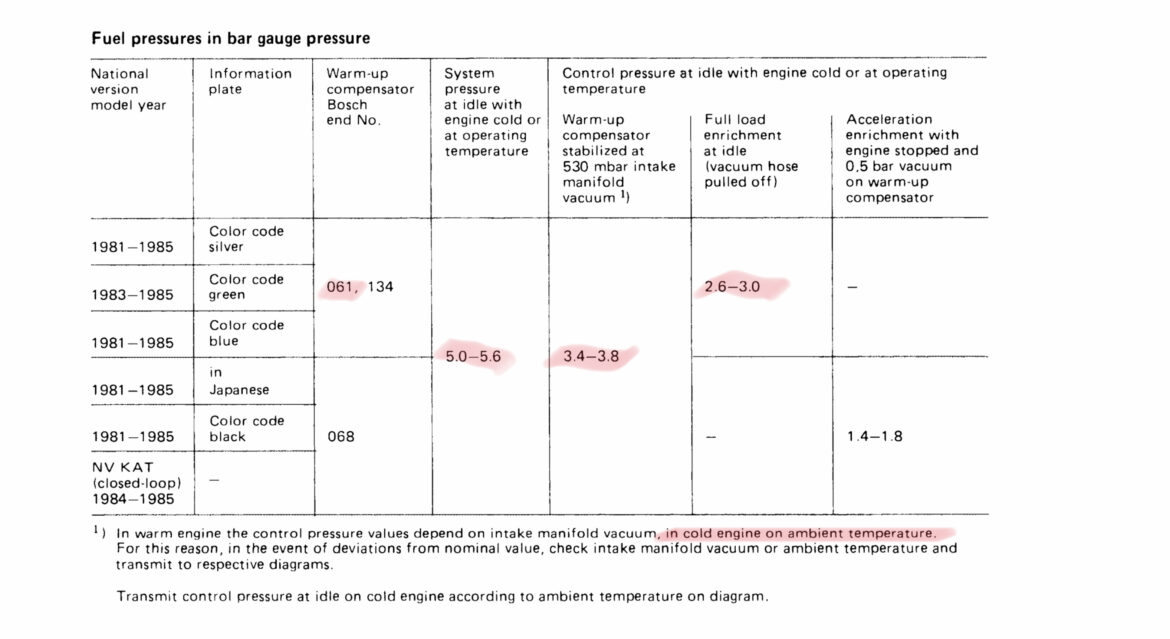

With a K-Jet CIS system nothing runs right if the fuel pressure is out of whack. It can lead to lean and rich running and this will of course mean rough running. Over the weekend I did some tests on the fuel pressures to see if there is anything amiss.

The fuel pressure test kit I bought is a generic eBay one. Note it’s not the K-Jet specific kit that retail for close to $200. This kit has all the bits and pieces needed to test the K-Jet injection pressures for a Mercedes-Benz and only costs $60-$70. It doesn’t have the banjo fittings the the K-Jet specific kits have, but they aren’t needed for Mercedes-Benz testing. I believe the banjo fittings are for testing on a Ferrari.

I also needed to check the intake manifold pressure. To do this I used this kit:

The Setup

To start with, I connected the gauge to the T-piece from the kit with the valve. I then needed to connect a couple of the brass fittings together to make up a piece that could connect to the control line of the fuel distributor. The other end of the gauge hooked up directly to the Warm Up Regulator (WUR) and I was ready to take my first readings.

Cold Control Pressure

Cold control pressure is tested as soon as the gauge is connected and the car is started. The expected pressure is based on the ambient temperature as shown in the following diagram:

Based on this diagram, with the inside of my garage being somewhere around 22 degrees on a sunny winters day, I’m expecting somewhere around 1.6-2.1 bar. I was measuring around 2.0 bar, so I was quite happy with this.

Cold System Pressure

The next test was simply to close the value on the pressure gauge and see how high the fuel pressure goes to measure the system pressure. The diagram below, shows that I should be recording between 5.0-5.6 bar. Again, I was quite pleased to see this move up to 5.4 bar. Onto the next test.

Cold Control Pressure At Idle With Full Load Enrichment (Vacuum Hose Pulled Off)

The next test was to open the valve again and pull the vacuum hose from the WUR. This again looked good at around 2.8bar – within the range of the “Full load enrichment at idle (vacuum hose pulled off)” spec.

I kept the engine running and kept monitoring as it warmed up. My car has always had a peculiarity where the idle would start to go really high at around 60 degrees coolant temperature. It revs at around 2000rpm at idle!

Warm Engine Control Pressure

What I noticed is that the fuel pressure started to drop! Now, you’ll not above that it says “In warm engine, the control pressure values depend on intake manifold vacuum”. So I switched off the car and hooked up my vacuum gauge as it describes in the manual and took a reading.

I measured around 400 mbar intake vacuum. This should result in a fuel pressure of around 3.5-3.9 bar. But I was getting around 2.8-3.0 bar. This is not correct!

Warm Engine System Pressure

I decided to shut the valve on my fuel pressure gauge and take another measurement of the system pressure. To my surprise the gauge did not move from 2.8 bar even though I could detect a change in the way the engine was running from not having fuel going to the WUR, indicating that the valve on my pressure gauge was working as it should.

So what does this mean? Well according to the service manual it’s one of 3 items:

- Faulty fuel pump

- Faulty system pressure regulator (Aka the Accumulator)

- Blocked fuel return line

Working from the bottom up, I don’t think a blocked fuel return line is the issue. I would need to be a large build up of debris for this to be the issue. The system pressure regulator (Accumulator) was replaced less than 12 months ago and also did not resolve my issues, so this really leaves the fuel pump as the most likely culprit. I have one of these on order and will try and get it replaced as soon as possible. Hopefully mid-week.

I’m also wondering if the issue is related to dirt in my fuel tank or a blocked fuel strainer. I’ve had the tank cleaned out before, so I don’t expect that to be the issue, but it’s something I’m wary of.