The 380SEC hasn’t been running at its best lately. It’s developed a misfire and runs like an absolute pig when it’s cold. It’s also had an ongoing issue where it revs way too high when the coolant temperature hits about 60 degrees – somewhere around 1800rpm in Park. I’ve also noticed the vacuum gauge shows a bit of a vacuum leak when it’s sitting at idle. It’s time to look at the Intake Manifold Gaskets.

As you can imagine, shifting from Park to Reverse at 1800rpm is not good for the transmission and not a particularly nice experience from the drivers seat as the whole car jolts violently into gear.

It’s finally time to address these ongoing issues and get the misfire attended too, so I dropped the car off at my local mechanic and asked him to change the intake manifold gaskets. The car is obviously taking air in when it shouldn’t and this is causing the high revs at 60 degrees and making it difficult to diagnose other issues.

I really had to plead with them to do this job, because it’s not a pleasant job to complete. The unpleasantness doesn’t come from the nature of the job itself, but rather from this being a 40 year old car with bolts that have never been removed in 40 years that have a nature of ceasing in place and having to be drilled out. Not to mention the other bits and pieces that are likely to break in the process.

Fortunately I have a good relationship with my mechanic. So they agreed to take on the job and got stuck into it.

The dismissed the misfire as most likely an issue with the ends of the HT leads which they will replace in due time and got stuck into the intake manifold.

They took their time being as careful as possible. They removed all the easy stuff like the air filter and fuel lines and started disassembling the intake manifold. This is where the headaches started – most of the bolts came out without too much trouble, but 2 of them had rusted in place and ceased, causing the heads to snap off when they tried to undo them.

Work had to stop until they could get those 2 bolts out! The worst thing about this is these 2 bolts were in one of the heads of the engine. Sloppy work here could mean the heads need to come out and possibly replaced. The called in a specialist they know who came out, had a look and promptly returned to his truck and left – “Can’t do it on that angle!”. Another specialist was called who also declined the job because he doesn’t work in the area – but he knew someone who could help. He came out and was up to the challenge. After a couple of hours work, he had the bolts removed and new threads ready.

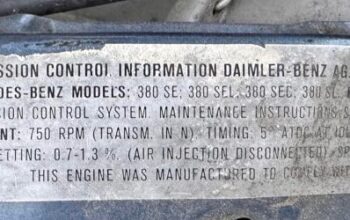

In the photo of the second thread, you can also see the discolouration around the bores – a sure sign that there was a vacuum leak coming from there.

Phew! It’s going to be easy now … nope!

When they removed the air flow meter prior to this, the hard rubber boot that attaches it to the upper manifold broke. This isn’t entirely unexpected as the rubber is 40 years old and had hardened like plastic. Fortunately, they new a local wrecker who had a couple of used air flow meters in stock, so off I went to pick it up. The wrecker was particularly helpful and gave me 2 to try. “They’ve got some minor damage, but shouldn’t cause you a problem. Just return whatever you don’t use”.

At this point I wasn’t exactly suer which part of the air flow meter we needed, so I took it back to my mechanic who checked them out. “No these won’t do, the rubber boot is damaged.” Bugger! A quick online search led me to some overseas suppliers who have them in stock. I can get aftermarket delivered in 3 days from the US for about $80 or genuine from Europe for about $300 but 2-4 weeks to deliver. Considering the car is off the road and partly disassembled, the aftermarket option was the only way to go. This car, despite being 40 years old is on full registration and used as my daily driver.

3 days became 5 days, but the part finally arrived at 9:20 on Friday morning. I wasted no time in dropping it off. It helps that the workshop is 250m from my home and I can just drop in when I need. I gave them the part then hastily returned home as I had a meeting I needed to attend.

At around 4:30 on the same day, I thought I’d check in and see how they’re going, fully expecting them to have been half way or more through the reassembly process.

“Sorry Mark, the parts no good”

“What!?“

“It might be off a 6 cylinder car or something”

”No it’s definitely right, I checked the part number and made sure it’s the right one”

“Come have a look. See how this teeth in the aluminium, it needs to be bonded to the boot somehow and the shape is slightly different. This doesn’t fit at all”

Distraught I went home and did some more googling and there it was. It’s the right part number, but Mercedes-Benz changed the design on the series 2 cars, so that the boot can be replaced on its own. What I needed was a series 2 air flow meter, so that I could use the new rubber boot I had purchased. I went back to my mechanic first thing on Saturday morning to share the news as I know that one of the air flow meters I picked up from the wrecker was from a series 2 car. The boot looked identical to the one I had purchased online.

“That’s great, but we returned them yesterday”

”No worries, I’m going to take the kids to their martial arts class and then I’ll go the wrecker and pick up the part, but I won’t be able to go until around lunch time”

I went back to the wrecker and explained what happened. He handed me the part and I asked him how much he wants for it – “Is your birthday coming up – Happy Birthday!”. Funnily enough, my birthday had just passed.

By now the mechanic had closed for the weekend, but I had the part and the boot. So I took it upon myself to try and fit it. I’d read online from a post a few years earlier that it could be a bit fiddly to fit and that people were resorting to clamps and other contraptions to hold it in place. To my surprise the original boot came off with no trouble at all (the mechanic had to use a knife to cut the old one out) and the new one fit almost perfectly.

With the workshop closed for the weekend, I had a bit of time to clean up the new air flow meter with some degreaser. I’ll dropped if off first thing on Monday morning. Hopefully things get easier from here.