My 380SEC has always run rough when it’s cold. I’m talking the sort of rough where it’s unresponsive to throttle input, rocks severely and comes close to stalling.

Considering that most of my fuel system has been attended to by my trusty mechanic, the next likely item to check is then warm up regulator (WUR). Now, I could have gone and bought a used warm up regulator, but I felt that if I had gone down this route and my problem is not resolved, I wouldn’t know if it’s actually the warm up regulator or something else.

So off I went and ordered a reconditioned unit from K-Jet Specialists up in Queensland.

The new WUR came nicely packaged in a sealed plastic bag with all the fuel and vacuum connections nicely plugged off.

To remove the WUR from the car there are 6 items to consider:

- 2 Allen bolts that attach the WUR to the engine

- 2 fuel lines

- 2 vacuum lines

To start with it’s easiest if the fuel lines are disconnected first. The 2 fuel lines use different sized fittings. One is a 12mm and the other is 14mm. This makes it easy to ensure they go back in the right way around.

After undoing this fuel lines, the 2 Allen bolts can then be unscrewed to release the WUR from its mounting bracket on the engine. Finally, the 2 vacuum lines can be slipped off. Be sure to note which vacuum lines connects to part of the WUR.

Once it’s off the car, it’s then necessary to swap then2 fuel line connections from the old WUR to the new one. I found that then connectors were quite stiff and difficult to undo and had to put the old WUR into a bench vice to make it easier to undo them. Once they ware out, the new WUR came with a couple of new copper washers that act as a gasket between the WUR and these connectors.

Installation was the reverse of this process starting with the vacuum lines, then the 2 Allen bolts and then the fuel lines.

During the installation, I noticed that one of the vacuum lines going to the auxiliary air valve to idle air distributor boot, had some silicon on the end. A closer look showed that the boot had actually snapped and someone had tried to silicon it back into service.

Furthermore, there is another connector that has been blocked off. On my 450slc, this second line is not blocked and has a vacuum line going to it. I have no idea what the purpose of this additional vacuum line is, but it’s something I need to investigate.

Once it was all back together, the next thing to do was a test drive. Unfortunately, the engine wasn’t cold when I did this work, so it wasn’t possible to see if it resolved my cold running issues, however the car did run nice and smooth when it was warm.

Interestingly, I found that when I returned from my test drive the idle was now slightly higher than it was previously, so I turned it back down. And took it for another drive. Following this second drive, I was satisfied that the far was running well again. I also noted that the slight hesitation it had when moving from a standstill was gone.

The following morning, I had to do the school drop off run for my daughter and this was a perfect opportunity to test the cold running performance. The car was definitely running better, albeit not perfectly smooth for the first couple of minutes. I suspect that it now needs a tune up to make sure that the fuel mixtures are correct. I also believe there is a vacuum leak that needs to be resolved as the economy gauge is lightly above where it should be when in park and way above when it’s in drive. Could this be from the broken boot identified above?

It was close to 24 hours before I had the chance to drive it again. It wasn’t a proper drive but I needed to start it up and park it on the street, so that I could get the 450SLC out. Unfortunately this time around it wasn’t running right, with basically no difference from the old WUR. Of course the total running time was less than 1 minute so maybe a longer drive would have found something different.

I’m hoping to replace the broken boot as soon as possible and will post back here afterwards. I’m not sure if any of the Local parts shops stock it and being the weekend, I’ll need to wait until Monday to find out. Worst case scenario it could be 2-4 weeks until I get a replacement from overseas. Also, the genuine part is no longer available, so I’ll need to settle for a URO brand part of questionable quality.

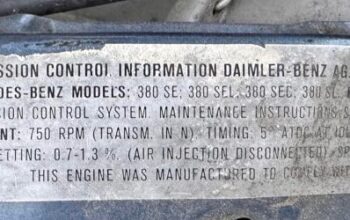

Hello, the dashboard of my Mercedes 380 slc year 1981 USA C107 has been disassembled. There is a problem to reassemble the air conditioning pipes. I would like the diagram for connecting vaccum. Thank you

The vacuum diagram in this post includes the air conditioning. It’s for a 450SLC but should be the same as the 380SLC.

https://formandmotion.com/vacuum-seat-locks-previous-owner-issues/